Environment

As a subcontractor to the wind turbine industry, we at BSB Industry feel a special obligation to work intensively with the environment. Nature is close to our hearts, and we care about the climate footprint we leave and the world we pass on to our children and grandchildren.

Sustainable measures

At BSB Industry, we focus on sustainable measures, a circular economy, recycling and a green approach to solutions. Energy saving, waste management and general environmental optimization are all active components in our production and general operations and also apply as an overall and mandatory premise in all new projects and processes.

We want to make a difference for the environment

At BSB Industry, we are committedly to reducing our energy consumption and carbon emissions, just as we have a constant focus on minimizing waste in production processes and other initiatives that help to make a difference.

Get a quote and choose to collaborate with a company where the climate mattersSustainable initiatives at BSB Industry are a win for the climate

Environmental management system 14001

At BSB Industry we have implemented the environmental management system 14001. With this ISO certification we create greater transparency and absolute certainty that we work seriously with the environment and the climate by choosing green energy, sorting waste, using recycled materials, producing on new and up-to-date machinery and by constantly focusing on climate-friendly decisionmaking that helps lay the foundations for a sustainable future.

Download ISO 14001 Certificate

More people must have access to sustainable energy

As a supplier to the major OEMs in the wind industry, we offer solutions that are essential in building energy infrastructure. Solutions such as Anchor Cages, transport equipment and bearing plates help ensure that wind turbines can be erected and give more people around the world access to renewable energy.

The substitution of fossil fuels has been a natural part of our journey. It makes good sense for us to invest in green electricity when we ourselves provide solutions that help promote sustainable development and reduce the footprint we leave on nature.

Last but not least, we work every single day to optimize our processes by shortening production time and other efforts so that energy consumption is reduced.

Get a quote and choose to collaborate with a company where the environment mattersVestas’ Sustainability Certificate

At BSB Industry, we are proud of our partnership with Vestas, where, together, we are committed to working for a sustainable future.

Read the story Vestas and BSB Industry in closer partnership

BSB Industry uses climate-friendly CO2-neutral welding gas

The Linde Green product range is approximately 7 percent more expensive for us. We at BSB Industry have decided to accept this added expense because we believe that we as a company in the “black” industry carry a special responsibility for the climate and for reducing our CO2 emissions.

The cutting and welding gas we get from tanks from Linde is made on green energy, and therefore contributes to us being able to achieve our common climate goals within the green transition of gas consumption. At BSB Industry, of course, we cannot make the difference alone. But we can help show the way for other companies in the heavy industry.

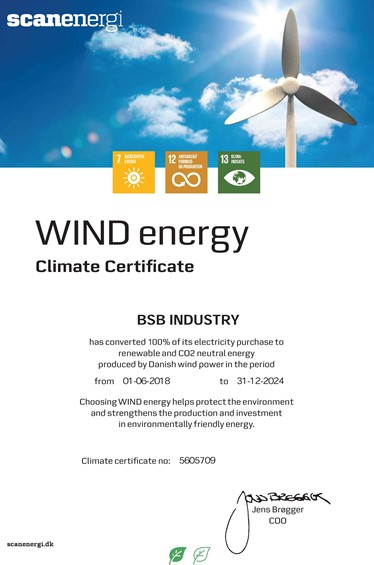

100 percent green energy

Since 2018, our production has run 100 percent on green energy produced by wind turbines. Of course, our lighting is by LED, just as the old gas heater has been replaced by an air to air heat pump. The heating of the buildings with the air to air heat pump by itself produces an annual CO2 saving of nothing less than 81 tons.

Efficiencies for the benefit of the climate are constantly under consideration and by installing a demand-controlled ventilation and extraction system we will save an additional 307,000 kilowatts per year.

Our factory in Ciechocin, Poland, runs on 100 percent green energy

At our factory in Polish Ciechocin, fossil fuels have been replaced with green wind energy, a fact of which we are of course proud. With the investment in 100 percent green energy, the factory reduces CO2 emissions by approximately 1,136,800 kilos per year or more than 1,100 tonnes.

In Poland, smog concentration is one of the densest in Europe, and air pollution is alarmingly high. As a larger company, we have a responsibility to run a more sustainable production and reduce our CO2 emissions.

We hope that our initiative will inspire our employees, other companies and the Polish society as a whole to take CO2 emissions and air pollution seriously.

Proud member of APQP4Wind

APQP4Wind is the common frame of reference to be used in the industry to strengthen the cooperation between Manufacturers and Suppliers.

APQP4Wind aims to make the process of product quality assurance demands as well as the product release process as clear as possible and have a vision to align and mature the global wind industry supply chain and to be the quality assurance methodology used by the entire global wind industry from design to end-user.

Learn more about APQP4Wind